GSL testing processes: top quality guaranteed.

Sound verification of customer requirements

In order to ensure the top quality of our castings, we regularly carry out a large number of tests on our processes and the cast products.

Our qualified testing personnel are available to you with the corresponding test approvals and certificates for all tests. We are also happy to take over the acceptance of orders ready for delivery in cooperation with you or a commissioned acceptance company.

On request, we can provide you with test certificates in the form of certificates of compliance with the order 2.1, factory certificates 2.2 or acceptance test certificates 3.1 or 3.2 in accordance with EN 10204.

Overview

GSL testing processes at a glance:

- Spectral analysis for the exact determination of the chemical composition of the casting material

- Hardness tests, tensile tests and notched bar impact tests to determine material properties, especially after heat treatment

- Magnetic crack tests and dye penetration tests for the evaluation of surfaces

- Ultrasonic tests, X-ray tests and computer tomography to check the internal quality of castings

- Pressure and leak tests on pressure-bearing components

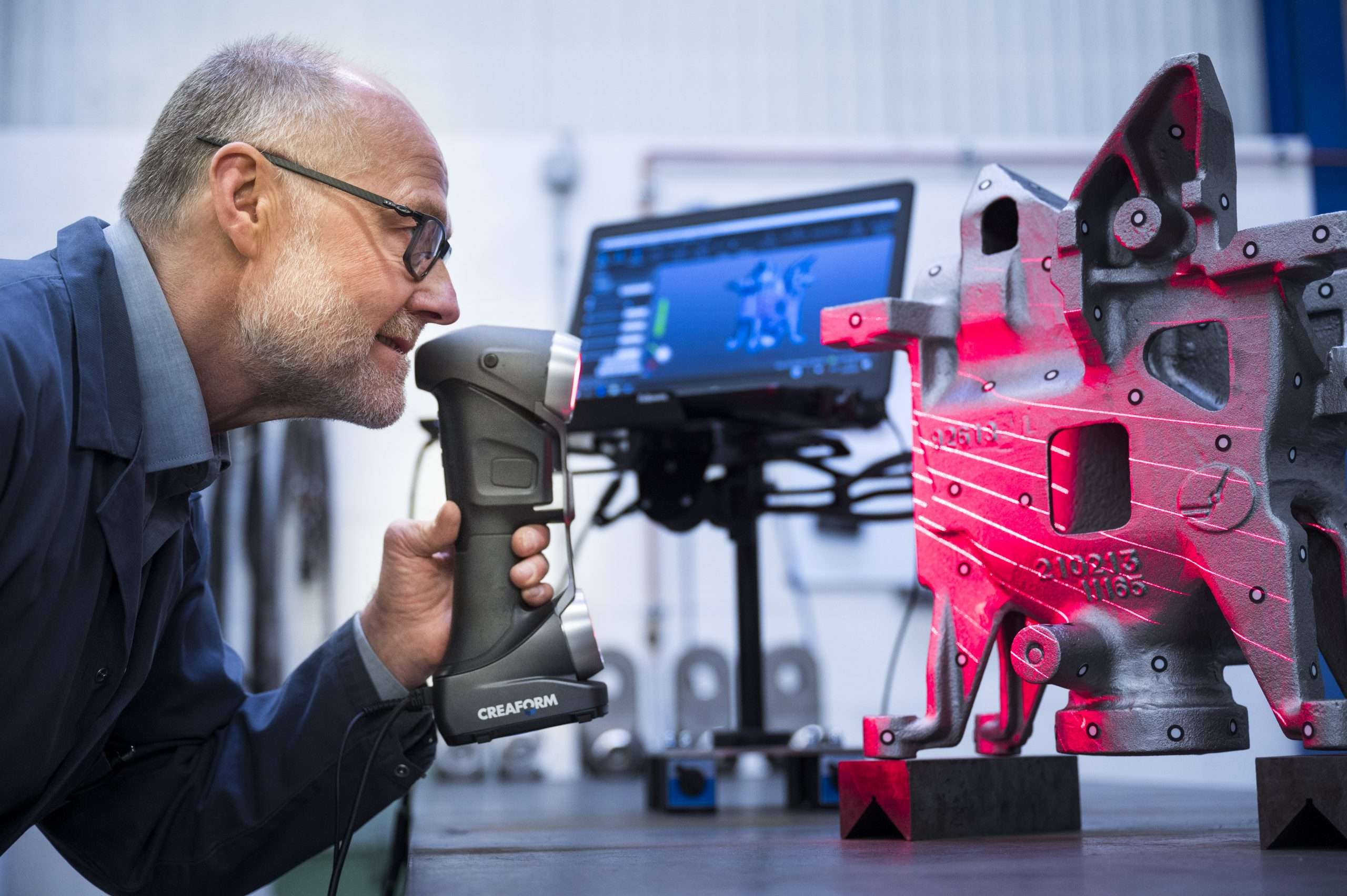

- Dimensional inspections by optical 3D-scanner

- Gauge, assembly and functional tests

Your direct contact.

We are always at your service. Simply give us a call.