GSL sand casting: flexibility for small and medium series

Cost-effective production using the nobake process

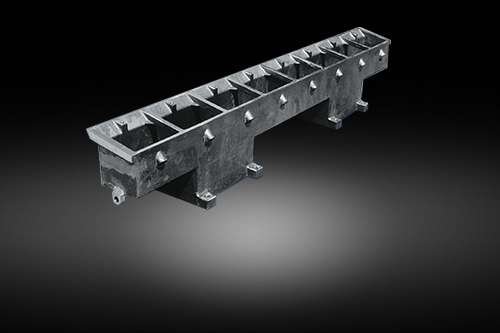

For the production of small or medium-sized casting series, we often recommend sand casting in the nobake process to our customers. The GSL sand casting process is particularly effective due to its flexibility: Not only can it be used for different component and series sizes, but also for all known cast steel materials.

Diversity is part of our daily work. Our trained foundry specialists produce over a thousand different cast products every year, several hundred of which are initial samples. This is only achieved with good training, a lot of experience and a great deal of enthusiasm for casting.

We produce the moulds for sand casting in our two moulding lines and one core shop. We use high-quality cold resins and basic moulding materials and continuously check the moulding material in our moulding material laboratory. Ninety-five percent of the moulding material is regenerated and reused after casting.

The molten steel is melted from high-quality steel scrap and alloying elements in 2 modern medium frequency furnaces with a melting capacity of 1.2 tons each. We use spectral analysis and temperature measurement to ensure the sound top quality of your castings.

All production specifications, experience and tricks for preventing faults are documented for each cast product in our knowledge management system and are subject to constant improvement. This is based on a constructive culture of dealing with faults and a high degree of personal responsibility on the part of the employees in production.

With GSL as your sand casting partner, all services are provided from a single source right from the development phase if required.

Overview

GSL sand casting making – the advantages for you:

- For small and medium series sizes

- Suitable for casting weights from 5–800 kg

- Large dimensions also feasible independent of standard moulding boxes

- Good dimensional accuracy and surface quality

- Suitable for core-intensive castings

- Suitable for all known types of steel castings

- High flexibility and short delivery times

- Economical small-batch production due to low-cost pattern equipment

Heat-resistant cast steel

Cement production

Heat-resistant cast steel

Cement production

Quenched and tempered steel casting

Cement production

Heat-resistant cast steel

Industrial furnace construction

Heat-resistant cast steel

Industrial furnace construction

Heat-resistant cast steel

Industrial furnace construction

High-manganese steel

Conveying and grinding technology

Quenched and empered steel

Conveying and grinding technology

Heat-resistant cast steel

Conveying and grinding technology

High chromium cast iron

Conveying and grinding technology

Quenched and tempered steel

Conveying and grinding technology

High chromium cast iron

Conveying and grinding technology

Quenched and tempered steel

Conveying and grinding technology

High chromium cast iron

Conveying and grinding technology

Quenched and tempered steel

Mechanical and plant engineering

Quenched and tempered steel

Mechanical and plant engineering

Quenched and tempered steel

Rail vehicle technology

Quenched and tempered steel

Rail vehicle technology

Quenched and tempered steel

Rail vehicle technology

Quenched and tempered steel

Rail vehicle technology

Quenched and tempered steel

Rail vehicle technology

Quenched and tempered steel

Rail vehicle technology

Quenched and tempered steel

Rail vehicle technology

Kent USA

Quenched and tempered steel

Architecture

Copenhagen

Quenched and tempered steel

Architecture

Constance

Quenched and tempered steel

Architecture

Your direct contact.

We are always at your service. Simply give us a call.