GSL quenched and tempered steel: strong and tough for high operational demands

Strength for highly stressed components

For components subject to high mechanical stress, the use of quenched and tempered steel is often the best solution.

Quenched and tempered steel is the name given to steel grades that contain, in addition to carbon, further alloying elements

such as chromium, molybdenum, nickel and vanadium. The addition of the alloying elements promotes

hardening capacity with greater wall thicknesses and improves the mechanical properties.

Quenched and tempered steels are in a multi-stage heat treatment after casting.

This process enables targeted adjustment of strength and toughness to suit the application.

GSL quenched and tempered steels – selected materials and areas of use:

– High-strength quenched and tempered steels for applications with high mechanical stresses

– Heat-resistant quenched and tempered steels for consistently high operating temperatures above 400 to approx. 600 °C

– High stability against temperature-induced plastic creep and changes in material properties

– Cold-hardened quenched and tempered steels with excellent toughness properties at low temperatures below -10 °C

– Optimal for applications in refrigeration systems, transport engineering and raw material extraction

– High-alloy tool steels with good temperability and wear resistance for use

in tools for forming, cutting, stamping, embossing, rolling or for similar applications

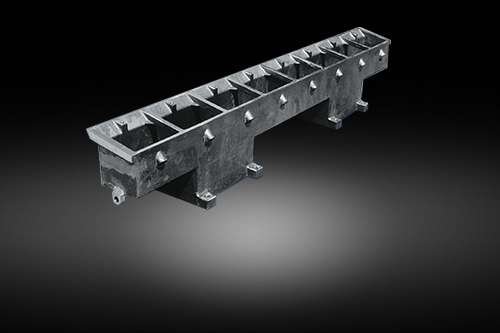

Sand casting

Cement production

Sand casting

Conveying and grinding technology

Sand casting steel

Conveying and grinding technology

Sand casting

Conveying and grinding technology

Lost Foam

Mechanical and plant engineering

Lost Foam

Mechanical and plant engineering

Sand casting

Rail vehicle technology

Sand casting

Rail vehicle technology

Sand casting

Rail vehicle technology

Sand casting

Rail vehicle technology

Sand casting

Rail vehicle technology

Sand casting

Rail vehicle technology

Sand casting

Rail vehicle technology

Kent USA

Sand casting

Architecture

Copenhagen

Sand casting

Architecture

Constance

Sand casting

Architecture

Your direct contact.

We are always at your service. Simply give us a call.