GSL high chromium cast iron: extremely hard-wearing.

For components with an outstanding service life exposed to frictional wear

Hard chromium cast iron is particularly suitable for components that are subject to heavy frictional wear.

Due to the low toughness of the materials, the components may only be exposed to low tension or bending loads.

Cast components containing up to approximately 3% carbon and 30% chromium, plus the other alloying elements

nickel and molybdenum, can be produced in

conjunction with the appropriate heat treatment to achieve outstanding wear values. A wide range of different

chemical compositions and heat treatments enables us to find

exactly the right chromium cast iron grade for your specific application.

The group of Ni-Hard materials or high-alloy tool steels is suitable for applications with higher demands on toughness.

Choosing the right wear-resistant material comes down to experience – and the intended use and the design

of the component must always be taken into account when making that choice.

We will be happy to share our experience to help you in this process.

Sand casting

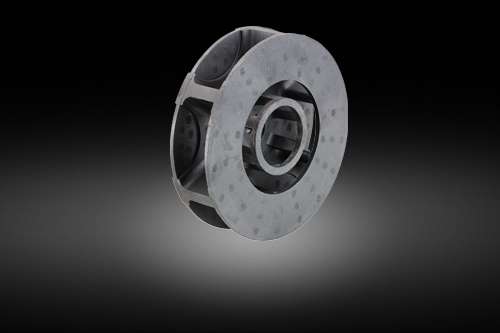

Conveying and grinding technology

Sand casting

Conveying and grinding technology

Sand casting

Conveying and grinding technology

Lost Foam

Mechanical and plant engineering

Your direct contact.

We are always at your service. Simply give us a call.